Across industries like automotive, construction, furniture, and more, FSI provides customised high-performance polyurethane system solutions. Our expertise ensures we meet your specific technical and commercial requirements, offering innovative systems for a wide range of applications.

Polyurethane System Solutions Customized for Your Success

India’s Leading Polyurethane System House

What sets us apart is our relentless commitment to deliver quality, innovation, customer satisfaction, technical support and meeting any other customer requirement.

Experience the difference a trusted partner makes.

Custom Polyurethane Solutions

We prioritize understanding each customer’s unique pain points, applications, and specific requirements, ensuring that our solutions are tailored precisely to their needs. Our flexibility extends to every aspect of our formulations. From foam free-rise and core densities and molded densities to reaction times such as cream, gel, and rise, we offer adjustable parameters to fine-tune our products to your exact specifications.

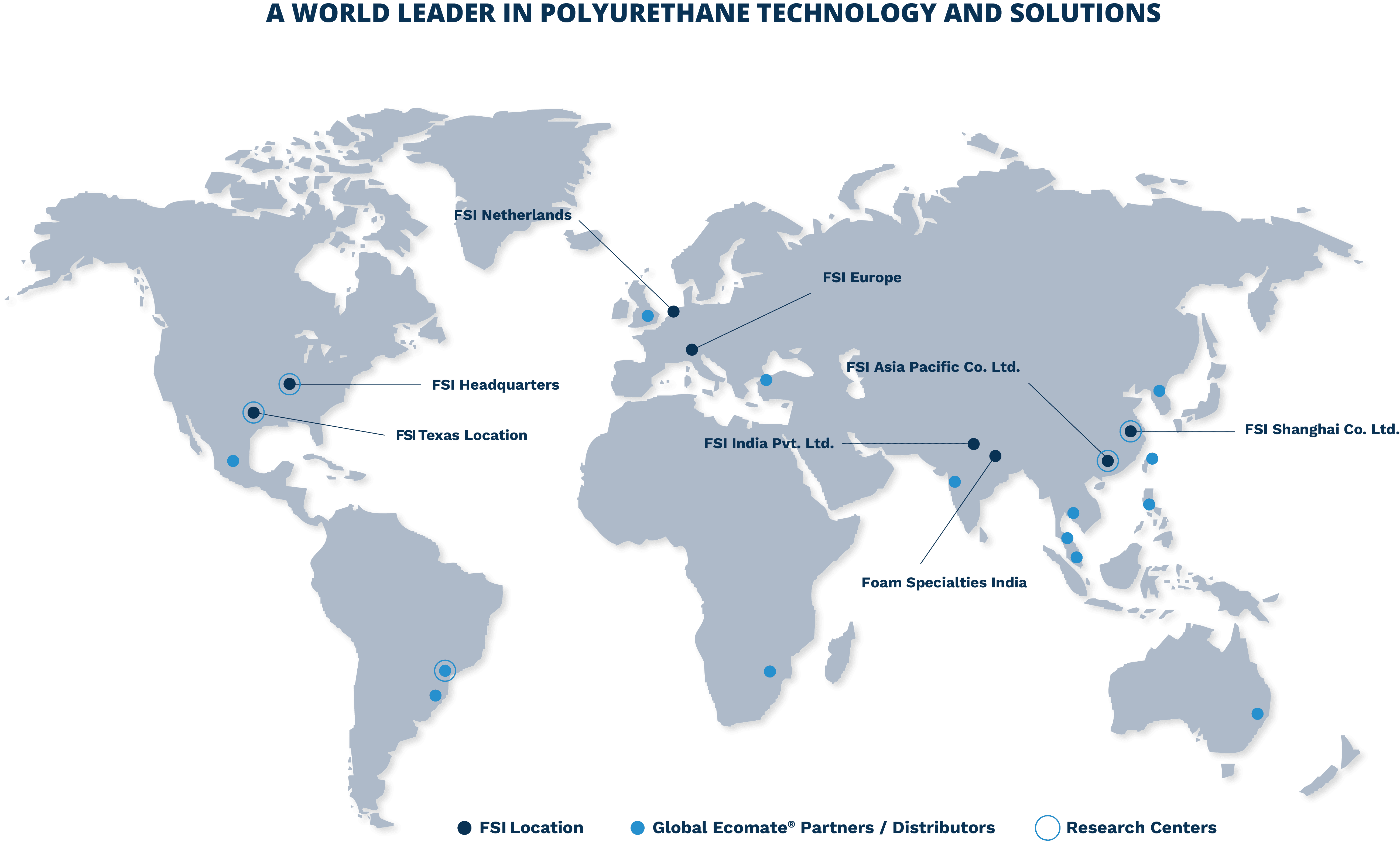

Locally Made & Globally Admired

Headquartered in Earth City, MO, USA, we have a broad international manufacturing footprint, serving diverse markets, including automotive, insulation and refrigeration etc.

Environment Friendly

In a world rapidly moving away from PFAS (per- and polyfluoroalkyl substances), FSI India is proud to lead with our Ecomate® solutions that are environmentally compliant and ahead of the curve.

Success Through Innovation

At FSI, “Success Through Innovation” isn’t just a slogan, it is our rolling history since our beginning in 1972. As a polyurethane systems house, we provide innovative high-performance polyurethane systems. We have patented technologies to improve performance of polyurethanes ranging from advanced chemistry and blowing agent technologies to cutting-edge dispensing equipment & applications.

Markets We Serve

Insulation

Continuous & Discontinuous Panels

Refrigeration & Cold Chain

Thermoware

Automotive

Mattresses & Furniture

Construction: Spray Foam & PUF Sheets

Pipe Insulation & Pipe Sections

Refrigerated Trucks

Marine Application

Why we are

Leading the Industry

FAQ’s About Polyurethane Foam

What is polyurethane foam (PU foam)?

Polyurethane foam is a versatile material produced from the reaction of polyols & isocyanates. It’s known for its excellent cushioning, insulation, and structural properties.

What is the chemical structure of polyurethane foam?

The chemical structure of polyurethane foam is based on the condensation reaction of an isocyanate and a hydroxyl-containing compound, usually a polyol. This reaction creates cross-linked molecules that form a flexible and durable foam when combined with a blowing agent.

How is polyurethane foam produced?

Polyurethane foam is produced through either a liquid injection foam or slabstock foam process, depending on the desired properties and intended use of the final product. Each method has its own advantages and disadvantages, so finding the right method for a specific application is key to achieving optimal results.

How strong is polyurethane foam?

The strength of polyurethane foam depends on various factors including density and formulation, but generally speaking it is known to be a very resilient and durable material.

What is polyurethane used for?

Polyurethane foam can be used for applications ranging from cushioning, soundproofing, impact protection, energy absorption, thermal insulation, packaging materials and more.

Is polyurethane foam environmentally friendly?

Most types of polyurethanes are non-toxic and considered environmentally friendly compared to other materials such as oil-based plastics or foams made with CFCs (chlorofluorocarbons).

Are there any health risks associated with polyurethane foam?

Generally speaking there are no health risks associated with using polyurethane foams but some individuals may be sensitive to certain components such as diisocyanates which may cause irritation when handled without proper protective equipment.

What are the 2 main types of polyurethane foam?

Flexible foam, which is used mainly in cushioning and upholstery, and rigid foam, which is used mainly in insulation and structural support.

What is a polyurethane systems house?

Polyurethane systems houses provide comprehensive solutions for producing polyurethane chemical systems, utilizing state-of-the-art production processes and customized options to ensure projects are executed with precision and accuracy.

How do I choose the right PU foam for my application?

Consider factors such as density, compression strength, flexibility, and fire resistance when selecting PU foam. Consult with us to ensure you choose the most suitable type for your needs.