In addition to our industry-leading polyurethanes, FSI offers a wide variety of high-quality PU foam dispensing equipment.

Foam Dispensing Equipment

Equipment by FSI

Made in America.

Built to Last.

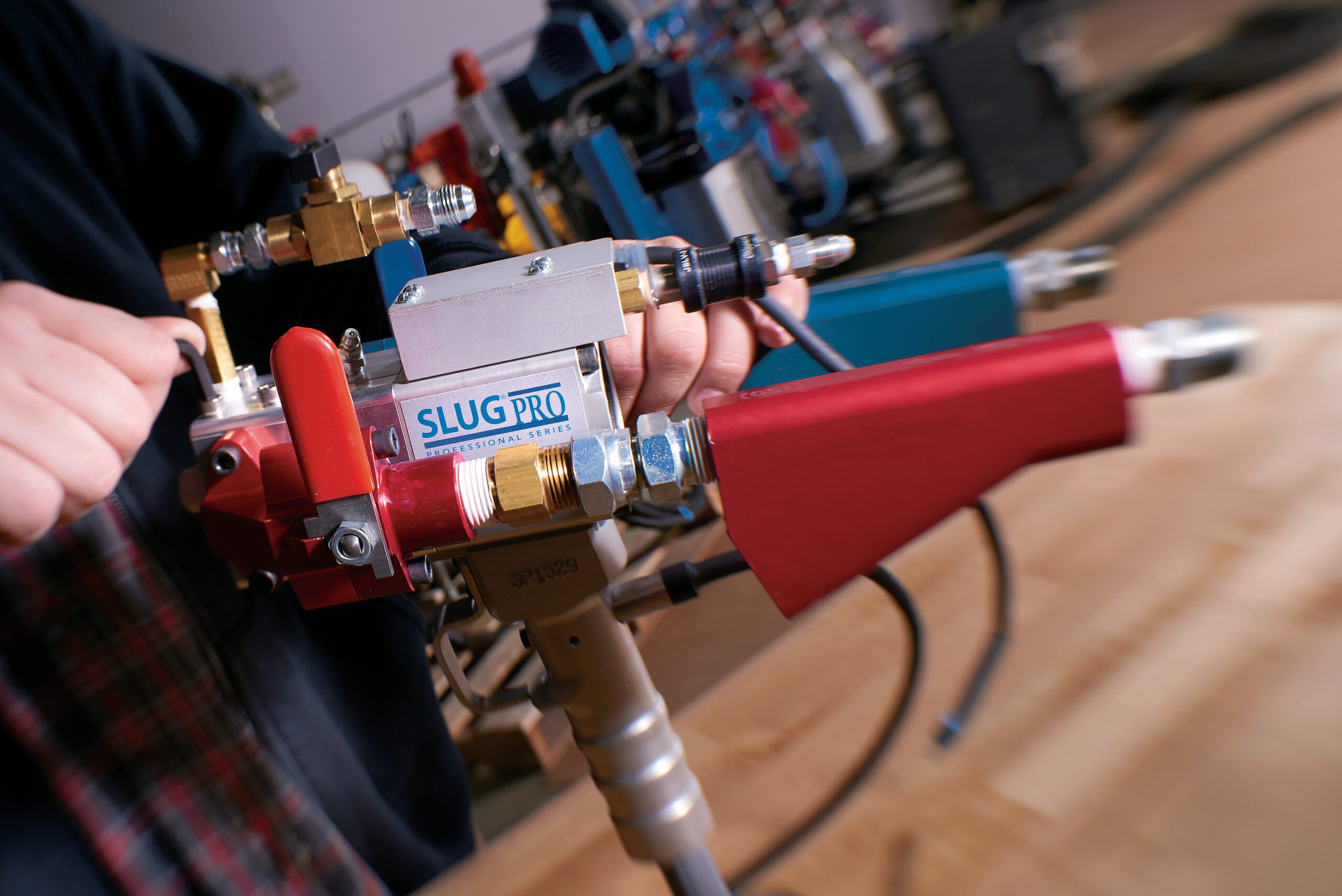

SLUG Pro

Advanced Pressurized Polyurethane Foam Dispensing Equipment

SLUG Pro or “Solvent-Less Urethane Gun” was the first of its kind, designed specifically to enhance worker safety and eliminate the need for flushing solvents, typically carcinogenic, which were in common use during its development and launch to market. The SLUG Pro is pressurized dispensing equipment with outputs ranging from 6 lb/min. to 60 lb/min. (~3 kg/min. to 27 kg/min.). It is ideal for pour-in-place applications and an economical choice for businesses who do not have ready funds or budgets to consider high-pressure dispensing equipment.

Polyshot Pro

Polyurethane Foam Dispensing Equipment

We developed the POLYSHOT PRO to literally “fill the gaps” – not just gaps that need foam, but the gaps in equipment choices. The POLYSHOT PRO is the perfect choice for customers who don’t need a sophisticated, costly, high pressure machine, yet do need something more durable and reliable than a disposable, plastic gun. Our Technical Group kept the end user in mind throughout the design process, and delivered a dispensing gun that is simple to use, withstands rigorous application environments, and is easy and inexpensive to maintain

Polyshot

Disposable Polyurethane Spray Foam Applicator

We developed the POLYSHOT™ as a solution to the ever-changing regulations within the spray foam industry. With harmful HFC’s being phased out, the need to have an alternative propellant presented itself. The POLYSHOT™ polyurethane dispensing applicator is the cost-effective choice for customers who need a high quality disposable spray foam applicator

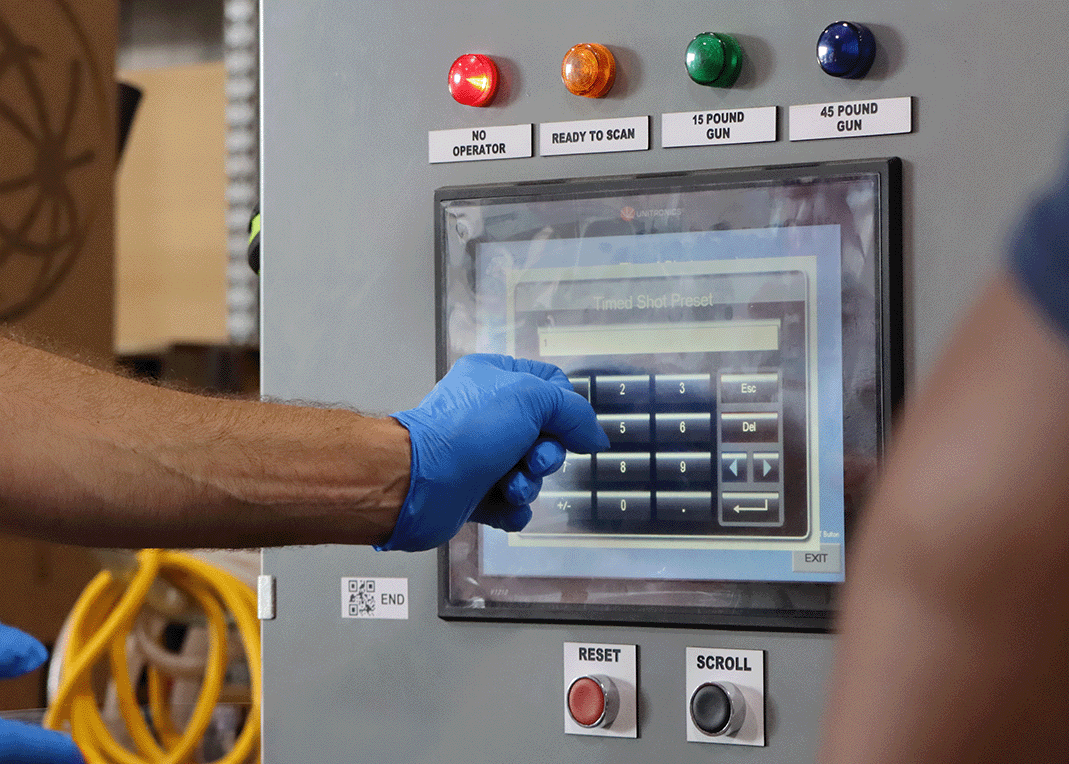

Onsite ACT

Advanced Control Tenchnology

Onsite ACT is a complete foaming and quality assurance system that integrates quality checks, condition monitoring, QR code scanners, operator access control, and more to guarantee your operation works smoothly and effectively.

We developed the Onsite ACT with a thorough understanding of the polyurethane production process experience and collaboration with customers. Onsite ACT provides a full range of dispensing options that can meet your specific needs and manufacturing requirements.

Tote to Tank

Chemical Transfer System

Save time and money by switching to the updated chemical transfer process. FSI’s modernized approach gives you complete control of your conditioning room’s quality assurance and safety features.

Streamlined process.

Improved efficiency.

The better option than pressurized tanks for chemical transfer because it’s efficient, safe, and less costly.

GRACO

FSI is an authorized Graco® distributor

We offer pumps, spray foam proportioners and guns in partnership with GRACO®, a leading equipment provider with proven experience in the construction, manufacturing, processing, and maintenance sectors.

GRACO produces a wide range of spray foam guns and adjacent equipment that provides proper output levels for small, medium, or large projects.

Explore GRACO solutions

Our partnership with GRACO complements nearly 50 years of foam product and process experience to provide unmatched turnkey technical assistance for our customers.

Global Reach

Tailored Support

FSI serves manufacturers on an international scale with a sales, production and distribution network that spans the globe.