GenFoam is a 100% water-blown rigid pour-in-place system that’s perfect for making molded parts like composite cores, flotation devices, decorative trim and even taxidermy! With outstanding performance compared to systems using HFCs, HFO/HCFOs, GenFoam is a great choice for businesses wanting to reduce their carbon footprint and help protect our planet.

GenFoam

Water-Blown Pour-in-Place Foam Systems

GenFoam is a Water-Blown Rigid Pour-in-Place Polyurethane System by FSI

GenFoam can help you make some of the world’s finest products, often at a lower cost than usual – with no extra time or money needed for production processes and equipment!

-

Easy Integration: GenFoam is designed for straightforward processing with standard pour-in-place equipment, eliminating the need for specialized tools or process changes.

-

Consistent Quality: Delivers a uniform cell structure and smooth surface finish, reducing scrap and ensuring repeatable part quality across production runs.

-

Versatile Application Range: Suitable for a wide variety of molded products—from decorative trim to taxidermy forms—allowing manufacturers to serve multiple markets with one system.

-

Lightweight, Rigid Performance: Provides excellent rigidity without excess weight, making it ideal for structural and non-structural parts where strength and handling ease matter.

-

Cost-Efficient Formulation: High yield and minimal waste help reduce overall material costs while maintaining production efficiency.

We’ve built our company around providing our customers with innovative solutions that won’t harm the environment, and GENFOAM® is a great example of how that commitment continues on. Powered by water, GenFoam has NO Global Warming Potential (GWP), NO Ozone Depletion Potential (ODP) and is VOC-exempt, meaning it does not create smog.

GenFoam meets the requirements of the Montreal and Kyoto Protocols and the Kigali Amendment, helping companies around the world make better products that are better for the environment.

Key advantages

- Zero Global Warming

- Zero Ozone Depletion

- VOC Exempt

- EPA / SNAP Compliant

- Low Emissive Foams

- Montreal Protocol Compliant

- Kyoto Protocol Compliant

- Kigali Amendment Compliant

The GenFoam family of products are fully formulated, water-blown rigid polyurethane foam systems for pour-in-place and molded foam applications. GenFoam meets the requirements of 33CFR §183.114 US Coast Guard Test of Flotation Materials (MILSPEC-P-21929B). It can be processed with high, low, and pressurized metering equipment. GenFoam is available in various container types for shipping and storage and has a shelf-life of six months. Please refer to the Safety Data Sheet (SDS) for specific storage and handling details.

Processing Conditions

Processing specifications should be determined by users for each product or application. If you have any questions, contact our technical services team, we’d be happy to help.

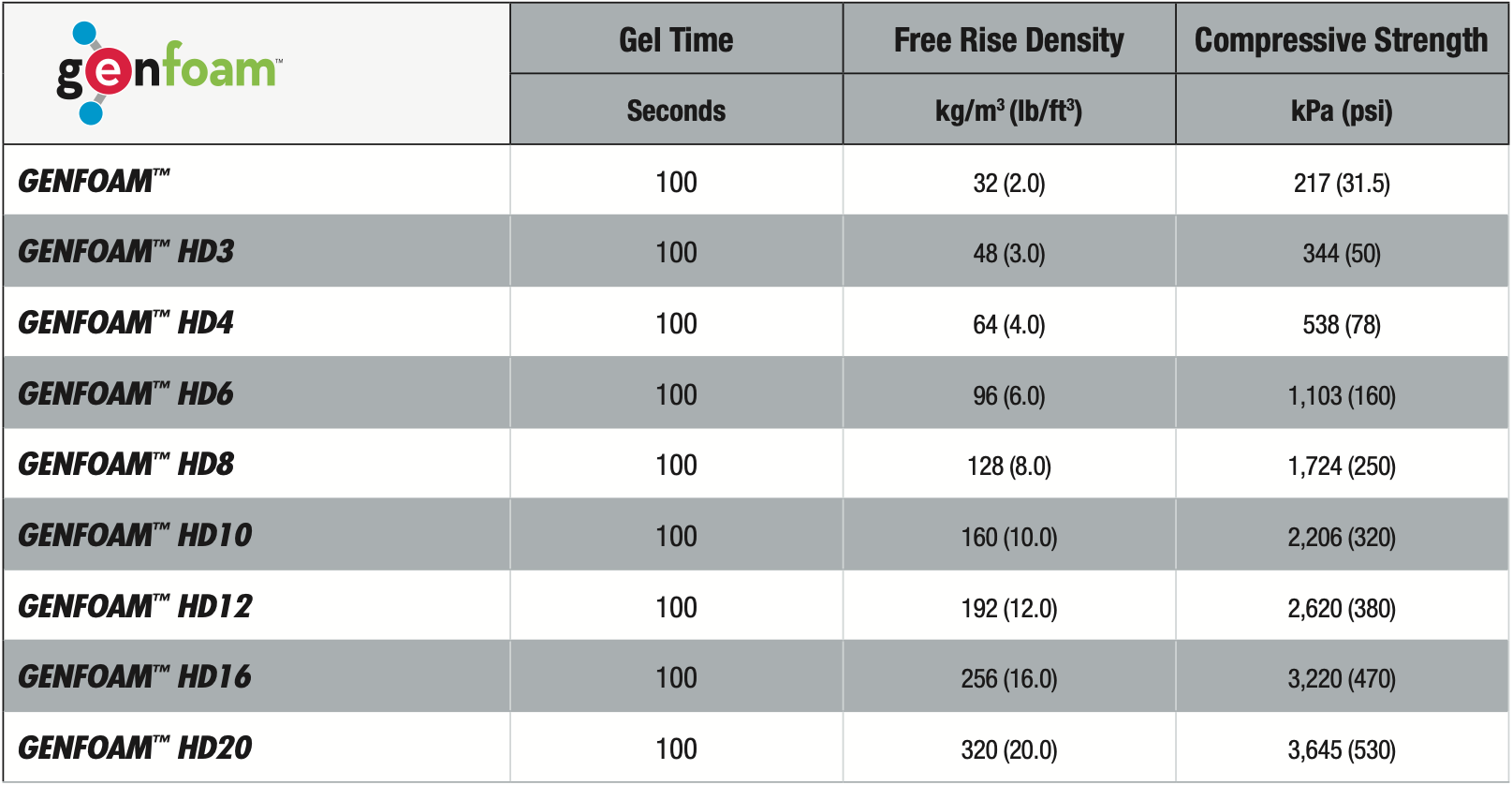

Typical Properties

Third Party Certifications