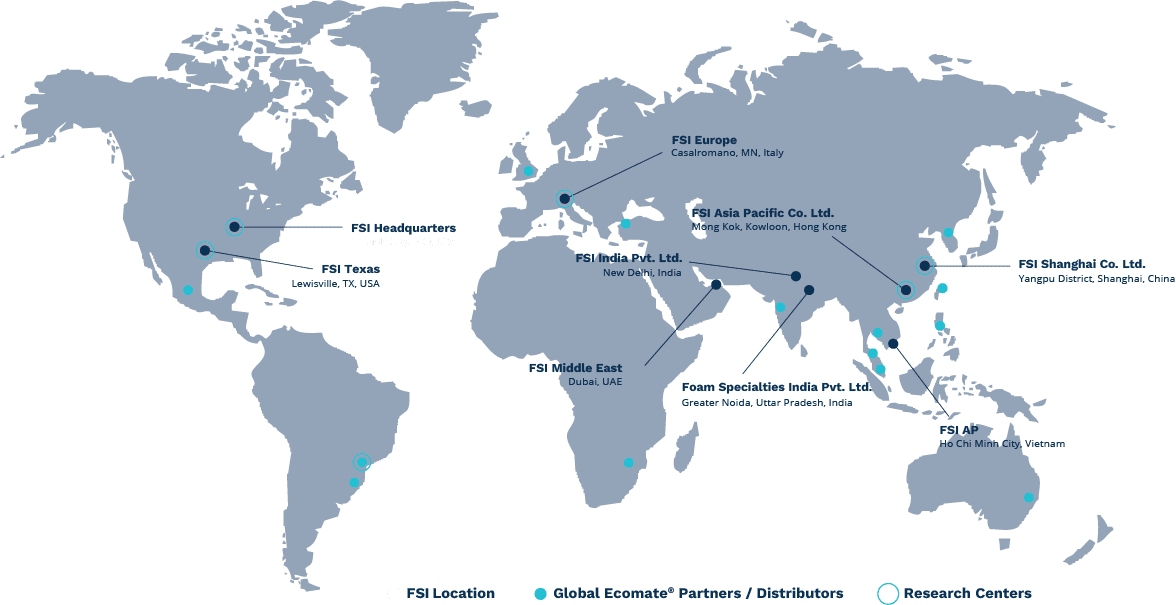

FSI combines cutting-edge polyurethane foam systems with an unrivaled dedication to technical service and support.

This unique blend, as well as our guiding values of caring, sustainability, and innovation, enable our customers to create products that advance the industry.