Advanced Pressurized POLYURETHANE FOAM Dispensing Equipment

SLUG Pro

SLUG Pro or “Solvent-Less Urethane Gun” was the first of its kind, designed specifically to enhance worker safety and eliminate the need for flushing solvents, typically carcinogenic, which were in common use during its development and launch to market. The SLUG Pro is pressurized dispensing equipment with outputs ranging from 6 lb/min. to 60 lb/min. (~3 kg/min. to 27 kg/min.). It is ideal for pour-in-place applications and an economical choice for businesses who do not have ready funds or budgets to consider high-pressure dispensing equipment.

Unleash Efficiency and Safety

The SLUG Pro isn’t just a foam dispensing gun, it’s a tool designed with user-friendly features to increase efficiency, save costs, and improve your bottom line. Here are some of the key features and benefits that set it apart:

KEY BENEFITS

- Low Cost with Industry-Best ROI

- Time/Cost-Saving Mix Head Rebuild

- Eliminates Solvent Disposal

- Supports Single & Multiple Drops

- Routine On-Site Technical Support

- Disposable Mix Cartridge

- Light Weight

- Line Heating

- Various Outputs

- US: 6, 15, 30, 45, 60 lb/min.

- Metric: 3, 7, 14, 20, 27 kg/min.

STANDARD FEATURES

- Air Open/Air Close Cylinder

- Direct Impingement Mix

- Timer

- Cleaning & Maintenance Kit

- Digital Ratio Scale

- 25 ft. hoses (7.6m)

OPTIONAL FEATURES

- Gun Mount Timer

- Custom Hose Lengths

- Pip System and Manifold Set-up

American Made

Pressurized dispensing was originally brought to market by our founder while working for Olin Chemical. FSI evolved the concept with the original SLUG using a “solvent-less” air purge model which removed the need for toxic pushing solvents. SLUG Pro is the latest evolution in FSI’s pressurized dispensing with all the reliability of previous designs but substantial improvements including an improved mix cartridge design.

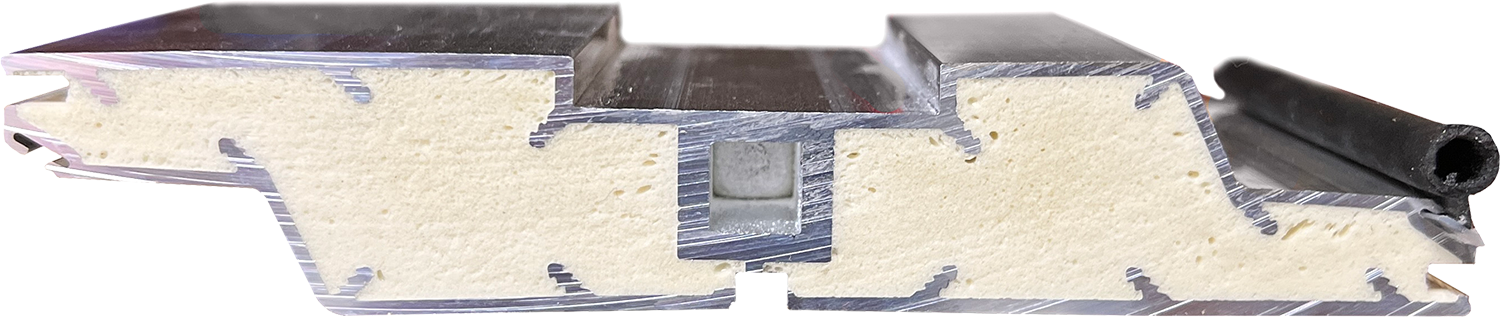

Top Grade Materials

We use top grade materials to make our equipment. The SLUG Pro is machined with precision from premium materials like 2024 T6 aircraft grade aluminum, brass valves, and Teflon-lined stainless steel braided hoses which are insulated and protected in a robust ballistic nylon sheathing. Despite using more expensive materials, we’re able to deliver complete, high-quality product at an affordable price.

Simple Design

Sophistication with a simple and focused design. We are mindful of an operator’s use and handling needs, hence we eliminated flashy and unnecessary parts which are ineffective and typically lead to unnecessary difficulty. The SLUG Pro is simple to use, simple to maintain, and simple to repair.

Quality Production

Each unit of the SLUG Pro is personally assembled by our experienced technicians to ensure compliance with our exacting standards. This approach allows us to focus on delivering quality products in a timely manner. Our equipment is not mass-produced—instead, it’s a product of dedicated craftsmanship and commitment to quality.

Customization For Your Needs

If our SLUG Pro does not meet your specific needs or fit seamlessly into your production process, we will be the first to recommend another path. Our team is well versed in analyzing processes and have experience in providing “turnkey” solutions that do not involve FSI’s equipment. We bring value by providing a necessary solution not by selling products. If you don’t need it, we won’t recommend it.

Reputation

“We Service What We Sell,” a key philosophy taught by our founder and a lesson we will not abandon. It is this fundamental attitude which has built our reputation and earns our customers’ trust. We like working hand in hand with our customers and know it is our reputation which helps set us apart.

Key Improvements

We’re proud to continue our history of innovation with the second generation of our revolutionary SLUG, offering these added benefits:

- A new disposable mix cartridge – which can be changed out in minutes – replaces the original SLUG block and eliminates the need for block reconditioning and exchange.

- An improved flow-meter design offers external chemical flow rate adjustment and greater ISO to polyol ratio latitude.

- A more robust solenoid valve provides a more secure connection and increased reliability.

- A higher maximum output rate of 60 pounds per minute.

- Universal color coding – red for ISO, blue for polyol.

Optimized for Your Operations

The SLUG Pro is specifically designed to excel in a variety of applications, making it a versatile addition to your operations. It shines in pour-in-place applications, providing a reliable and efficient solution for this specific task with a range of outputs, from 6 lb/min. to 60 lb/min. (~3 kg/min. to 27 kg/min.).

Picnic Coolers

Insulated Panels

Boating & Marine

HVAC Insulation

Appliance Insulation

Global reach.

Tailored support.

FSI serves manufacturers on an international scale with a sales, production and distribution network that spans the globe.